grinding mill discharge density

Optimum SAG Mill Discharge Density - Grinding Classification

P80 sag mill product is the 80 % passing particle size in sag mill discharge is true, and about solid, I mean solid content of ore (%) in sag mill (mass of dry ore/ (mass of dry ore+mass of water) S Sturmbann 8 years ago Like As % solids increases the P80 from

اObtener precio

Grinding Mill - an overview ScienceDirect Topics

An hydrocyclone is to be installed in a closed circuit grinding circuit with a mill discharge containing 30% solids by volume. The solid density is 2800 kg/m 3 and the density of

اObtener precio

Steady-state and dynamic simulation of a grinding mill

2020年6月15日 Andreas Kugi c , Ian Keith Craig a Add to Mendeley https://doi/10.1016/j.mineng.2020.106208 Get rights and content • A dynamic non

اObtener precio

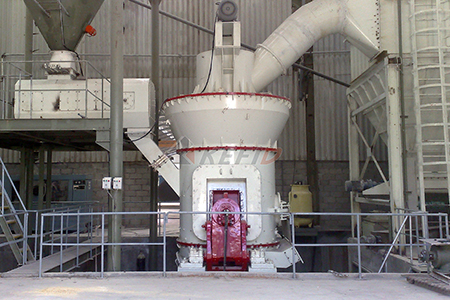

Measuring Density in Grinding Circuit - Rhosonics

Measuring points. In the grinding circuit, possible installation points are in the ball mill discharge and feed (recirculation), (hydro) cyclone feed, overflow, and underflow. Example of a Rhosonics density meter (SDM),

اObtener precio

Slurry flow in mills: grate-only discharge mechanism (Part-1)

2003年7月1日 1. Introduction Typically in wet overflow grinding mills the product is allowed to exit the mill by overflowing the discharge trunnion. The driving force for flow

اObtener precio

Should the slurry density in a grinding mill be adjusted as a

2007年7月1日 Slurry density influences the ore transportation through the grinding mill (Laplante and Redstone, 1984, Gupta et al., 1981, Hintikka et al., 1999) and the

اObtener precio

Measurement of Slurry Properties and Load Behaviour in

1988年10月1日 Sensitivity Analysis: Estimation of mill discharge fractional solids content Basis: Mill feedrate 100 tfh 200% circulating load Solids density = 3 t/m3 75% solids in

اObtener precio

Operation Analysis of a SAG Mill under Different

2020年10月9日 Simulation results under the ∅5250 × 500 mm mill model show that the mill operates with the optimal effect when the mill is under the condition of 80% critical speed and 15% fill level; the ...

اObtener precio

Slurry flow in mills: grate-only discharge mechanism (Part-1)

2003年7月1日 It is shown that with mill discharge flow-rate, discharge density, and volumetric hold-up measurements, the model states and parameters are linearly

اObtener precio

Analysis of specific discharge rate functions in industrial

2015年4月1日 A correlation between discharge rate and mill throughput rate increase was found to exist (Genç, 2008). Sub-factors influencing the material discharge through the

اObtener precio>> Next: Máquinas De Rectificado Y Rectificado Dec

Mas noticias

- proceso de lixiviacion en arena de silice

- suministros de molino de bolas

- procesamiento de oro en reno

- fabricante líder de equipos para la perforación de la construcción de pozos de gas natural

- gayatri concasseur de pierre adilabad

- minas de oro de buritica

- fresado de procesamiento de cobre y oro

- proceso del final del molino de cemento

- máquina trituradora para la fábrica de cemento

- fábricas de babcock

- harina de maíadz molinos de sudía1frica

- proyectos de unid triturora de piedra en gujarat

- maquina trituradora de piedra vendedor en la india

- fabricantes de gomas de migajon

- costos de la planta de caolín

- clasificación la gravedad

- puede nghien thuy luc mdp 8 90kw

- unidad de trituracion de escoria eaf

- 500 ton per hour crusher price

- forjado de cobre molino de bolas en humedo

- eje de doble martillo de trituradora de piedra de cal

- fuente de recuperaci de azufre

- programa de mantenimiento de la trituradora de mandibula

- hecha en méxico trituradora de grava

- planta de cemento en bhutan

- trituradora de mandíbula 500mm

- maquinaria y molinos

- po fazendo moinho de esfera curto moinho de bolas

- c3mo calcular el costo del agregado en la trituradora de piedra

- planta de trituradoras en jaipur