hammer crusher defects

The Common Failures of Hammer Crushers - JXSC Machine

2019年3月9日 Design and machining defects, installation, debugging, maintenance process problems and man-made operation errors and structural wear and tear, deformation is the main source of hammer

اObtener precio

7 Hammer Crusher Common Problems And Solutions

Vibration factors. Poor lubrication, bearing wear and failure. V belt tension is too large. Improper maintenance methods. The environment temperature

اObtener precio

7 common faults and solutions for Hammer crusher

2019年10月8日 7 common faults and solutions for Hammer crusher. Amanda Lee. ImportExport trade sales manager at Henan Yaan Electrical Insulation Material Plant Co.,ltd. Published Oct 8,...

اObtener precio

(PDF) Impact wear in mineral crushing - ResearchGate

2006年1月1日 Several authors have reported high severity wear damages in hammer crusher [2, [11] [12][13], jaw crusher [1,3] and ball crusher

اObtener precio

Study of the Energy-Power Parameters of the Crushing Process in

2023年3月6日 Research goals: development of analytical method of determination of energy-power parameters of the drive of the hammer crusher with the grate;

اObtener precio

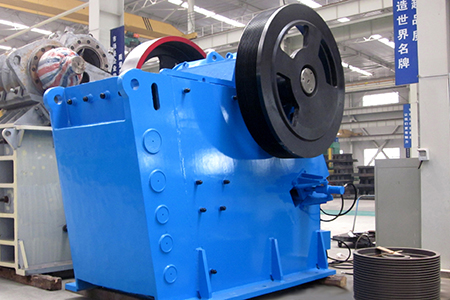

On the broken machine hammer manufacturing process

2012年8月14日 Hammer the core components of the crusher, hammer surface or internal manufacturing defects such as shrinkage, cracks, transgranular, not only will reduce

اObtener precio

Roller crushers in iron mining, how does the degradation

2021年4月1日 Several authors have reported high severity wear damages in hammer crusher [2], [11], [12], [13], jaw crusher [1], [3] and ball crusher [14] components at the

اObtener precio

Chemical composition of hammer material. Download Table

Crusher suffers from complex abrasive–impact load during the comminuting the mineral ore in processing plants, which induce severe damage and defects that can result in a

اObtener precio

Determining the residual resource of the hammer

Most of these crushers have a service life of 10 to 13 years and are objects with low reliability. Mostly emergency stops occur due to the destruction of the rotor bearings. In

اObtener precio>> Next: Cabeza De Trituradora De Hormigón Para La Venta

Mas noticias

- pantalla hummer molino

- mineral de máquina de trituración nombre

- granito y explotacion de minas plan de negocios

- trituradora de cono de alquiler indonesia

- difference between raymond mill

- trituradora de cono endurecimiento

- trituradora móvil para la venta en china

- triple rodillo producto

- 7 ft cone crusher for sale

- cerca de cantera

- cono de piedra caliza trituradora móvil Angola precio

- trituradora de quijada usada en mexico

- de la mandíbula comparación y la trituradora de impacto

- moedor para fazer de cálcio em pó

- trituradora marca roca

- moagem ultrafina xangai

- mining gold mining equipment

- lt105 trituradora de orugas sbm

- precio clasificador espiral de oro

- para la trituradora de piedra en uttar pradesh

- planes gratuitos para la construcción de una trituradora de filtro de aceite

- fabricantes de los eeuu del molino de la barra

- high pressure micro powder mill for milling ore

- trituradora de piedra trituradora de listitaly precio tph

- planta de molino de bolas para el fabricante en punjab

- piedra de la maquina trituradora de yakarta

- bateria de molinos de viento

- de escombros cementos

- trituradora pc vertical

- planta móvil trituradora de piedra en tamil nadu